High Strength

Duplex stainless steel achieves nearly double the strength of standard austenitic stainless steels.

Vastmaterial delivers high-performance duplex stainless steel castings with superior corrosion resistance and dimensional accuracy.

Engineered for demanding industries, our precision components optimize strength and reliability.

All Products

Discover austenitic stainless steel grades 304 316 and more with corrosion resistance properties applications and supply options

Pacific Alloy Casting NiHard castings deliver ASTM A532 abrasion resistant white iron wear parts for mining cement and asphalt applications

Austenitic stainless steel 304 316 sheets plates coils pipes with high corrosion resistance weldability and non magnetic performance

Discover high-performance 2205 duplex stainless steel bolts, offering superior corrosion resistance, strength, and custom fabrication for demanding industries like oil & gas.

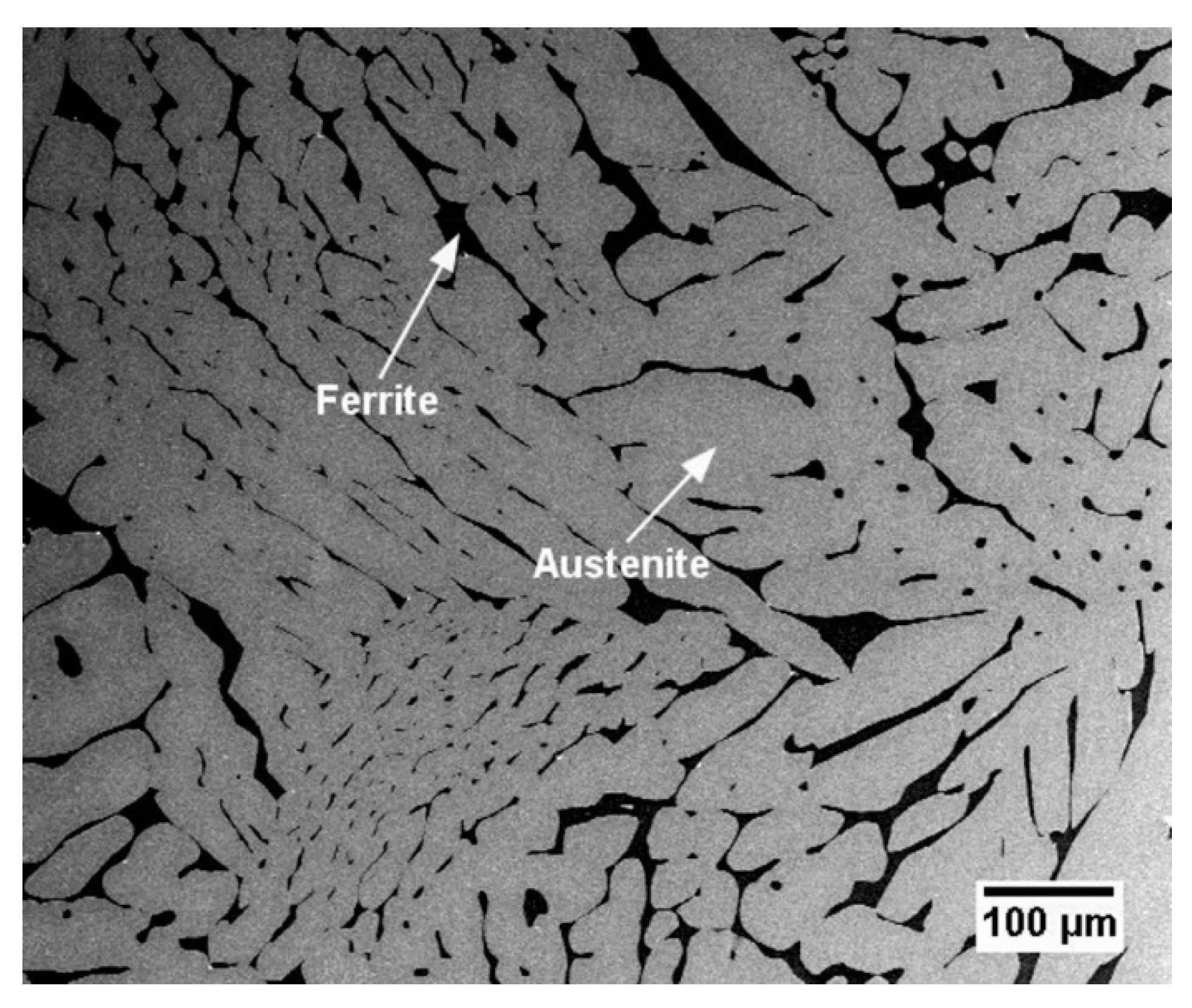

Duplex stainless steel combines austenitic and ferritic structures, enhancing strength and resistance.

Its dual-phase structure ensures excellent resistance to chloride stress and pitting corrosion.

Increased durability reduces maintenance costs and extends service life in aggressive environments.

Duplex stainless steel achieves nearly double the strength of standard austenitic stainless steels.

Maintains mechanical properties at elevated temperatures, ideal for industrial applications.

Microstructure improves resistance to abrasion and erosion in harsh conditions.

Suitable for chemical processing, oil and gas, marine, and more diverse industries.

Lower thermal expansion leads to better dimensional control during welding processes.

Longevity and recyclability contribute to sustainability goals while ensuring performance.

Vastmaterial specializes in precision casting of duplex stainless steel, enabling robust parts with superior corrosion resistance and mechanical strength.

Our tightly controlled process window ensures optimal microstructure formation, balancing ferrite and austenite phases to enhance durability and toughness.

With advanced mold design and filtration technologies, we minimize casting defects and deliver consistent high-quality components.

Tight control of temperature and chemistry ensures duplex phase balance that meets stringent standards.

Use of zirconia ceramic foam filters reduces inclusions, improving surface finish and mechanical properties.

Our castings perform excellently in aggressive environments due to well-controlled microstructure.

Vastmaterial products excel in highly corrosive environments, extending equipment lifecycle and reducing maintenance.

Engineered for mechanical stress tolerance, Vastmaterial components maintain integrity in extreme loads and temperatures.

Combining advanced metallurgy and innovative manufacturing, Vastmaterial offers proven solutions that optimize corrosion resistance and strength across industries.

Vastmaterial offers a comprehensive range of Duplex Stainless Steel grades

engineered for superior corrosion resistance and mechanical strength. Choose

from standard and super duplex grades tailored to demanding industrial

environments.

Vastmaterial’s Duplex Stainless Steels deliver optimal performance across

oil and gas, chemical processing, and marine applications.

Duplex stainless steel castings combine austenitic and ferritic microstructures to enhance strength and corrosion resistance.

This balanced structure provides superior performance in harsh environments, including chloride exposure and stress corrosion cracking.

Typical castings exhibit a refined grain boundary and uniform phase distribution for maximum durability and impact resistance.

Proper heat treatment and precise control during casting ensure optimal mechanical properties and structural integrity.

Employ state-of-the-art microscopy to verify duplex stainless steel phases, ensuring optimal corrosion resistance and strength.

Implement ultrasonic, dye penetrant, and magnetic particle testing to detect imperfections without compromising material integrity.

Conduct tensile, impact, and hardness tests aligned with industry standards to guarantee performance under demanding conditions.

Use specialized corrosion assays to assess material stability in chloride-rich and aggressive environments. These procedures are part of rigorous quality testing protocols.

At Vastmaterial, we provide tailored workflows and seamless engineering collaboration to deliver precise results for your projects. Learn more about our customized solutions.

Our precision casting process ensures corrosion and impact resistance in every custom-engineered part.

We utilize porous ceramic foam filters to eliminate impurities and enhance material integrity.

Vastmaterial offers tailored alloy solutions optimizing durability and performance.

Our engineers collaborate closely with your team to customize workflows, ensuring transparency and responsiveness throughout every phase.